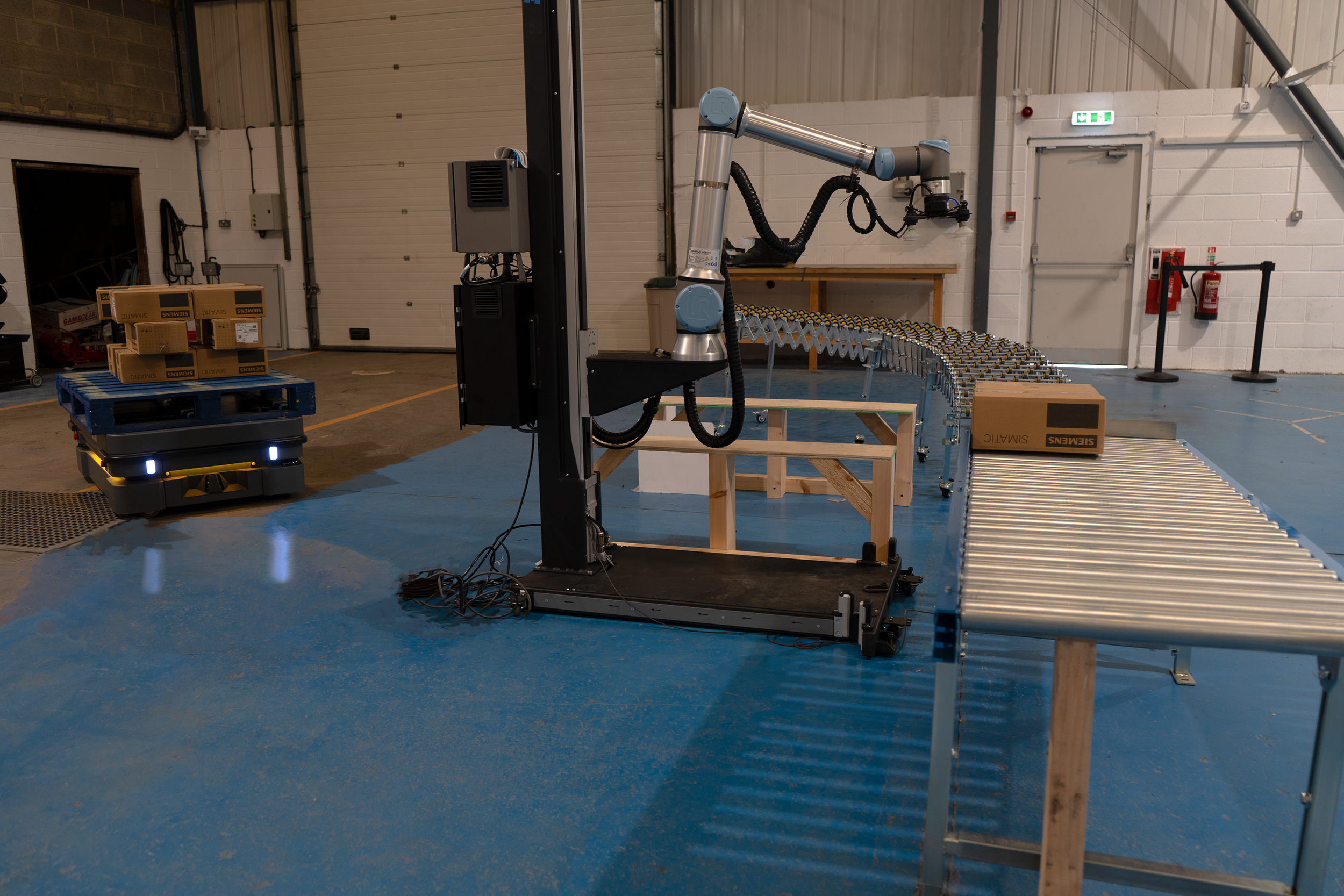

Robotics and Automation

Smart Technologies Made Smarter

Industry 4.0 emphasises modular flexible work environments based on autonomous robotic systems, automation and a range of other smart technologies. In the age of digitalisation, all but a few industry sectors rely on these technologies to optimise operational performance, achieve productivity goals and keep pace with demand.

Technologies

Industry 4.0

Industry 4.0, Edge Computing and Smart manufacturing is the result of effective integration of smart technologies to create an intelligent work process capable of thinking, communicating, adapting and consequently Smarter Working. Without these technologies, organisations will likely become uncompetitive or artisan.

What you can expect:

· 30% to 400% productivity improvements

· 60%-100% (Lights out) plus reduction in time spent walking/driving/carrying

· 99% Pick/Place accuracy

· 24/7 Constant/repeatable/reproduceable performance

· Immediate ROI

· Competitive advantage

If you are considering Robotics and automation as part your process improvement our team is ready to help you achieve your goals and enable you to start working smarter!